www.stanleysreef.org

STANLEY'S REEF TECHNICAL INFO HDPE Y SHAPED TUBULAR SURFING REEF

TECHNICAL INFORMATION

A removable, submersible reef has been designed after more than 10 years of research and development. The reef is designed to dissipate wave energy offshore and replenish sand along beaches, while producing waves suitable for surfing. The reef has been designed, engineered and patented in the USA with patents pending world wide by Highwave Sports Systems. Additionally, its relative low cost, environmental inert properties, half-life features of high density polyethylene, ease of manufacture, flexibility and engineering attributes make the material and the engineering design of this reef ideal for this application as supported by industry data and Highwave Sports Systems testing.

Reef Design

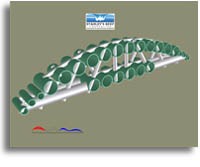

The Highwave design incorporates an approach called "nesting", whereby, HDPE pipe is nested together to form a "Y" shaped reef. The evolution of the "Y" came from informal tests conducted at Scripts Institute with engineering studies performed by Oceaneering Technologies. There is an advantage to initializing the breaking of a swell offshore along a "Y"shaped reef. Using HDPE pipe in a "V" configuration, with an outboard leg producing a "Y" shape, dissipates waves offshore and encourages sediment in suspension to settle in and behind the "V" portion of the reef. The advantages of the HDPE pipe building material include it's history of use in the ocean, it's ability to be structurally sized to meet specific size requirements and it's ability to be filled with wet sand or concrete for ballast and or air flotation that can be flooded. This smooth, safe reef design will produce a good wave for surfing and foster growth of inter-tidal plants and animals with specific habitat zones for abalone, lobster and fish.

These facts will assist permitting with support from those interested in marine habitat. It will also encourage entrapment of sediment behind this uniquely designed structure as demonstrated in tank tests.

Construction / Deployment / Mooring Design

The structural "Y" shaped reef will be assembled in a commercial harbor or on the beach and towed to the site where the air would be forced out with water. The reef will be sunk and be parked on the bottom. The designed ballast load and the hydrodynamics of the "V" portion of the "Y" are like airplane wings steering the structure downward. This design combined with screw anchors and mooring technology, will ensure no movement of the structure. By design, the front of the structure will not be in the wave zone. The aggressive ballast, anchoring and mooring in the front is insurance against movement after the structure is parked. Key also is the encouragement of silting in the structure and as well behind the "V' section which will serve as a redundant anchoring system. This is not a structural necessity but it will become an additional anchoring mechanism. Real time testing will enable us to forecast timetables for "silting" of the reef along various beaches, relative to coastal littoral flows. Simply dumping sand off a barge in front of the reef will quicken process as shown by our testing. Removal of a fully silted reef will be accomplished by introducing air into the air chambers and through the use of high pressure hoses by divers to help remove sand around the inside of the structure.

Advanced Design Concepts

The overall design of the structure gives rise to advantage of a strong, single body geometric shape. The preferred angle between the legs of the "V" section is 90 degrees allowing additional advantages to construction. The forward leg combined with the "V" section (making a "Y") bends wave energy to the forward and front "V" portion of the reef. Wave energy coming in from one side or the other (north or south swell) will dissipate on that side. The wave will break predominately on one side of the reef leg. This dynamic protects the sand cell behind the reef from any swell angle. The "V" protects the sand accretion behind the structure from all swell directions. The design will also help protect sand inboard of the reef from some long shore currents. The reef design can be up or down for virtually any wave climate and beach slope. The dynamic nature of the winter-summer pattern has been anticipated in the design. Once the design is proven in a "real-world" setting, a computer model will dictate the appropriate production size for a reef given the environmental characteristics of a beach. Sizes have been studied and determined for specific beach slopes.

Project Area / Morphology / Baseline

The Seacliff or Oil Piers area is ideal for a demonstration with this design for several reasons.

1. This area has had an extensive network of Oil Piers that have helped keep the sand cell together. The Piers were removed with erosion of the area and new sand down stream being observed.

2. There are no structures near the site.

3. The Beach is armored on both the west and east side of the sand cell.

4. A fifty year tradition of surfing in the area was lost with the pier removal in 1998 and the 101 off ramp destroying Stanley's 100 yards to the southeast in 1970. The return of any waves for surfing and potential host habitat would be supported by the whole community.

The project area is down coast (south east) of a point and is an elbow that traps an aggressive small sand cell or pocket beach approximately 1/2 mile long. The overall morphology is the result of a freeway built parallel to the beach in 1971. Data and aerial photos supply some baseline information on historical sand profiles. Pier removal requirements (documentation, photographs, etc.) over the last few years give new ongoing valuable data to help design and ascertain the potential effectiveness of this project. The erosive cliffs above the beach provided sand nourishment until the freeway blocked this with ineffective, clogged culverts.

Wave Climate

Seacliff beach area faces south west and has some large wave attenuation that is due to a small man made offshore island northwest off the site. This area sees slightly reduced wave climates being several feet smaller than well exposed northwest facing beaches up coast. Up coast creeks and sand cells deposit sand offshore in the project area during the winter months. The typical swell brings sand ashore in the summer. Armor rip rap protecting the freeway prevents sand accretion on the two boundaries of the project area. Heavy winds in the Santa Barbara Channel produce short

Click

diagram to enlarge

interval

waves

that break on this sand cell

from west-northwest. This area is partially blocked from south swells

in the summer by the offshore Channel Islands. Typical tides have a range

of approximately 6 feet.

INSTITUTIONAL INFORMATION

Site Ownership

The demonstration site has been released back to the California State

Lands Commission with the end of a 63-year lease to Mobile Oil Company

at the end of 1998. The oil lease included access roads and tidelands

that accessed by the oil piers. The area has always had access to the

public. The site bordered by land owned by the Railroad, Caltrans, California

State Lands Private land. Monitoring is already provided for by Mobile

Oil through the 2003 due to the pier removal requirements mandated by

the California Coastal Commission. The 1999 report is due and should be

available soon.

Permitting Requirements

Permits are required for a coastal project in California. Agencies involved

in the approval and permitting of this project include the California

Coastal Commission, California State Lands Commission, Army Corps of Engineers,

California Boating and Safety, California Fish and Game, Air Quality Control

District, and the County of Ventura. The project will be built on land

and installed in a matter of days. Furthermore, it can be removed in less

than a week. This will minimize air quality control issues. Section 227

This section relates to a specific act of Congress to find innovative

private sector technology that will help reduce or slow active shore erosion.

The Army Corps of Engineers has been selected to determine the best projects

from the private sector. Currently this "Y" reef project is a finalist

in the selection process and is supported by both district Army Corps

offices in California. Final determination should be made by the end of

October 2000. We will get permitting and monitoring only when this project

is selected. No funding for development or construction is included in

the application.

SUMMARY

Summary

The HDPE Tubular Surfing Reef is a design that has evolved over the last

10 years. There have been over two dozen models designed, built and tested

at venues such as Scripps, UCSB and private wave tanks. Tests determined

scouring, anchoring, durability, sand retention and wave quality. Habitat

studies include comparisons of pipe textures to support marine life and

abalone habitat in live tanks. A 1/6 scale ocean model tested various

features including scale issues and remove-ability. The success of this

system will yield an efficient wave energy breaking modular reef that

will force the waves and water energy further offshore with anticipated

sand accretion behind the structure. This reef would increase the efficiency

of beach nourishment projects by helping to retain the sand. The structure

will quickly become a living reef with a multiplicity of habitat attracting

marine life.

This reef will help manage shore erosion problems in a unique and cost

effective way while providing an excellent wave for surfing and increased

marine habitat.

Stanley's

Reef Foundation is a Non Profit Organization.